The word “slabs” comes from the Latin word “sheets” or “sections”. In the ceramic tile industry that is popular for use in countertops of kitchens because of its thickness and durability. one of the most cutting-edge processes now available involves the production of ceramic slabs employing cutting-edge equipment. The dimensions of a slab are much bigger than those of a typical tile. The specific purposes in mind will guide the determination of these parameters. In recent years, there has been an increase in the production of ceramic slabs, which can be attributed to the widespread use of modern tools and devices as well as the progression of technological advancements. On the other hand, the use of this particular type of ceramic in the interior design of buildings is becoming increasingly common. Things are getting progressively worse as time goes on.

a ceramic top for the table

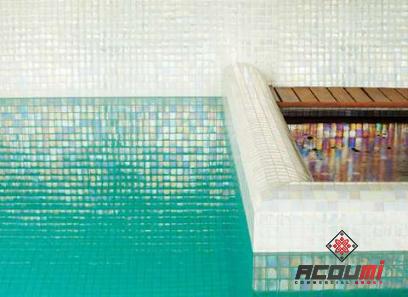

Architects are gravitating toward the use of ceramic slabs as a material of choice right now. These tiles’ low joint count (for more information regarding this characteristic, see the article Types of Tile Layout), unwavering durability, and breathtaking beauty have contributed to their meteoric rise in popularity over the past few years. Slab ceramics, on account of their immense size, are a great choice for presenting large surfaces in commercial settings in order to make an effect on the eye. This is because slab ceramics are an excellent choice for presenting large surfaces. Additionally, it adds to the overall sleekness of the design. Ceramic plates are an excellent choice for renovation projects because of their thinness. It is possible to produce one-of-a-kind slabs that will captivate the attention of any observers by adding a variety of effects to the body, such as metallic, sugary, matte and shiny, or streaking in the body.

Because of the natural qualities of the slabs, certain varieties of ceramics can now be used in conjunction with a variety of other kinds of flooring materials, such as stone or wood. This kind of ceramic is used in a great number of high-end residential, office, and commercial projects because the slab is of such stunning beauty and has such good quality. When implementing forward-thinking strategies for the interior design of buildings, it is now usual practice to employ huge slabs rather than little tiles. Large slabs with dimensions such as 244 by 120 centimeters, 360 by 240 centimeters, and so on are utilized in the area in order to provide a sense of genuineness to the environment. Porcelain tiles are typically used in kitchens and bathrooms, and their thickness can range anywhere from 6 to 12 millimeters (12 mm). The largest slab that can be purchased has dimensions of approximately 10 feet by 5 feet. If you want to use granite or quartz slab for things other than kitchen countertops, including flooring and wall coverings, the price of acquiring huge volumes of material can be out of your price range. Putting these priceless items in place will, of course, require a financial investment. It is recommended that you obtain enormous porcelain slabs in order to alleviate the tension.

ceramic tile kitchen countertops

ceramic or tile can be the best selection for countertops in the kitchen. The countertops in the kitchen are both a distinguishing feature and an essential component of the overall design of the interior of the building. If you choose an inappropriate surface for the counter table, it will have a detrimental effect, both aesthetically and practically, on the space. A kitchen may be made more beautiful, functional, and pleasant to work in all at the same time by selecting the appropriate countertop for the space. Because of the significance of this choice and the importance it has, you will undoubtedly be faced with the question of which surface is superior to the others and more ideally suited for your kitchen counter. Because of the consistent amount of moisture that is present in kitchens, there is a limited selection of surface materials that can be used for kitchen countertops.

Ceramic kitchen tiles for export

Ceramic kitchen tiles for export

It is never a good idea to use porous and non-resistant surfaces like wood, laminate, or fake stones for kitchen countertops because they are easily scratched by knives and other sharp implements and worn down by contact with hot dishes and other items. In addition, they are easily scratched by other items, such as pots and pans. Stone kitchen tables have been highly desirable for a very long time because of the natural elegance and beauty that they possess. Natural stone is a choice that is not only durable but also kind to the environment and affordable when it comes to kitchen countertops. Do you agree that installing a countertop made of natural stone is an essential component of any kitchen renovation or construction project? According to historical accounts, among all naturally occurring construction materials, the stone is the one that stands out as being the most resilient, opulent, and long-lasting.  Natural stone is a great material for use in residential construction due to its minimal upkeep requirements as well as its resilience to rot, mold, severe temperatures, and humidity. There is also a reflection of modernism, as well as freshness and inventiveness. A stone-topped countertop for the kitchen. It is recommended that natural stone be used in kitchens due to its inherent lack of toxicity, as well as the absence of any potentially hazardous chemicals or man-made components that could be hazardous to both people and the environment. When food is made directly on a stone surface, there is no risk to human health from consuming the materials used in the processing of the food because there is no intermediary step. One further undeniable fact about stones is that they contain positive energy and traits, which, when utilized by their owners, contribute to both the spiritual and physical well-being of individuals who do so. It is said that granite stone fosters cooperation and maintains harmony in relationships, while marble stone makes it possible for a person to get control of their thoughts and arrive at a place of inner peace. Because of how well they perform their function as countertops, premium stones can even create an increase in the value of a home. When building a new home or remodeling an existing one, you have access to hundreds of different kinds of stone from which to pick; yet, due to the abundance of available options, making a decision can be challenging.

Natural stone is a great material for use in residential construction due to its minimal upkeep requirements as well as its resilience to rot, mold, severe temperatures, and humidity. There is also a reflection of modernism, as well as freshness and inventiveness. A stone-topped countertop for the kitchen. It is recommended that natural stone be used in kitchens due to its inherent lack of toxicity, as well as the absence of any potentially hazardous chemicals or man-made components that could be hazardous to both people and the environment. When food is made directly on a stone surface, there is no risk to human health from consuming the materials used in the processing of the food because there is no intermediary step. One further undeniable fact about stones is that they contain positive energy and traits, which, when utilized by their owners, contribute to both the spiritual and physical well-being of individuals who do so. It is said that granite stone fosters cooperation and maintains harmony in relationships, while marble stone makes it possible for a person to get control of their thoughts and arrive at a place of inner peace. Because of how well they perform their function as countertops, premium stones can even create an increase in the value of a home. When building a new home or remodeling an existing one, you have access to hundreds of different kinds of stone from which to pick; yet, due to the abundance of available options, making a decision can be challenging.

ceramic tile kitchen countertops

In the majority of homes, the countertops can be found in the kitchen, the bathroom, and even the outside areas with various thicknesses and materials like ceramic or tile, wood, etc. Despite the fact that many contemporary house owners like to supplement their desks with additional components, such as chairs, Because of this, natural stone worktops, which include those used for flooring and vertical surfaces like fireplace surrounds and sprinkler heads, are gaining popularity in residential settings. Marble, granite, and quartzite are three fantastic materials that may be used for making countertops; in addition to these, you also have the choice of choosing a thickness for your countertop that is not only practical but also aesthetically pleasing. Worktops for your kitchen and bathroom should be selected with consideration given to their function, the thickness of the stone they are made of, their attractiveness, and the length of time they will be put to use. It is recommended to have some prior knowledge, despite the fact that educated professionals can undoubtedly explain the benefits, limitations, and applications of different stone thicknesses. 1.25 inches is the standard thickness for countertops made of natural stone in spaces such as kitchens, bathrooms, and other locations. This thickness gives the necessary strength and stability to create an impenetrable surface without the requirement of a plywood backing by providing the necessary strength and stability.  It is standard procedure to attach a slab of this thickness directly to the cabinet when installing prefabricated countertops, as this eliminates the need for seams (unless you have an unusually large surface or an odd shape that exceeds the largest slabs available). When deciding which stone to use for the countertop, you should take into consideration the following aspects: If you intend to construct a large overhanging space, such as a bar with seating, you should give some thought to the benefits of using thicker stone. In comparison, a stone that is one and three-quarters of an inch must be held in place. If a countertop has a thickness of 1.25 inches and extends more than 8 inches beyond the cabinetry, there is no need for any additional support. In general, thicker cuts of marble tile, granite, or quartz worktops cost 1.25 times as much as thinner cuts, but they are superior in terms of both visual appeal and practicality to the alternatives that are thinner. This is feasible due to the fact that thicker stone enables a greater variety of design options, such as the elimination of seams or the addition of a bulge. Because this slab does not have any edge seams, and because the plywood backing does not need to be covered as it would be with thinner panels, the countertops can be customized to have a wide range of edge patterns. Contact us if you’re planning to install a new floor. We offer a wide range of flooring options, including ceramic, tile, and hard-installed flooring.

It is standard procedure to attach a slab of this thickness directly to the cabinet when installing prefabricated countertops, as this eliminates the need for seams (unless you have an unusually large surface or an odd shape that exceeds the largest slabs available). When deciding which stone to use for the countertop, you should take into consideration the following aspects: If you intend to construct a large overhanging space, such as a bar with seating, you should give some thought to the benefits of using thicker stone. In comparison, a stone that is one and three-quarters of an inch must be held in place. If a countertop has a thickness of 1.25 inches and extends more than 8 inches beyond the cabinetry, there is no need for any additional support. In general, thicker cuts of marble tile, granite, or quartz worktops cost 1.25 times as much as thinner cuts, but they are superior in terms of both visual appeal and practicality to the alternatives that are thinner. This is feasible due to the fact that thicker stone enables a greater variety of design options, such as the elimination of seams or the addition of a bulge. Because this slab does not have any edge seams, and because the plywood backing does not need to be covered as it would be with thinner panels, the countertops can be customized to have a wide range of edge patterns. Contact us if you’re planning to install a new floor. We offer a wide range of flooring options, including ceramic, tile, and hard-installed flooring.

Your comment submitted.